Cutting Metals: Hy-Def Plasma vs. Laser

When it comes to metal cutting, precision and efficiency are paramount. Two popular technologies used for this purpose are High-Definition (Hy-Def) Plasma Cutting and Laser Cutting. Each method has its advantages and specific applications, and understanding the differences can help you choose the right one for your needs.

What is Hy-Def Plasma Cutting?

High-Definition Plasma Cutting is an advanced form of plasma cutting. It uses a high-velocity jet of ionized gas (plasma) to cut through metal. The "high-definition" aspect refers to the improved precision and edge quality compared to conventional plasma cutting.

What are the advantages to Hy-def plasma cutting?

- Cost Effective: Hy-Def plasma systems are generally less expensive to purchase and operate than laser cutting systems. The consumables and maintenance costs are also lower.

- Versatility: This method can cut through a variety of conductive metals, including steel, stainless steel, aluminum, brass, and copper. It's effective on thick materials, often up to several inches.

- Speed: Hy-Def plasma cutters can cut metal quickly, making them ideal for high-volume production environments.

- Edge Quality: While not as precise as laser cutting, Hy-Def plasma provides a much cleaner cut than traditional plasma, with minimal dross (residue) and a smaller heat-affected zone.

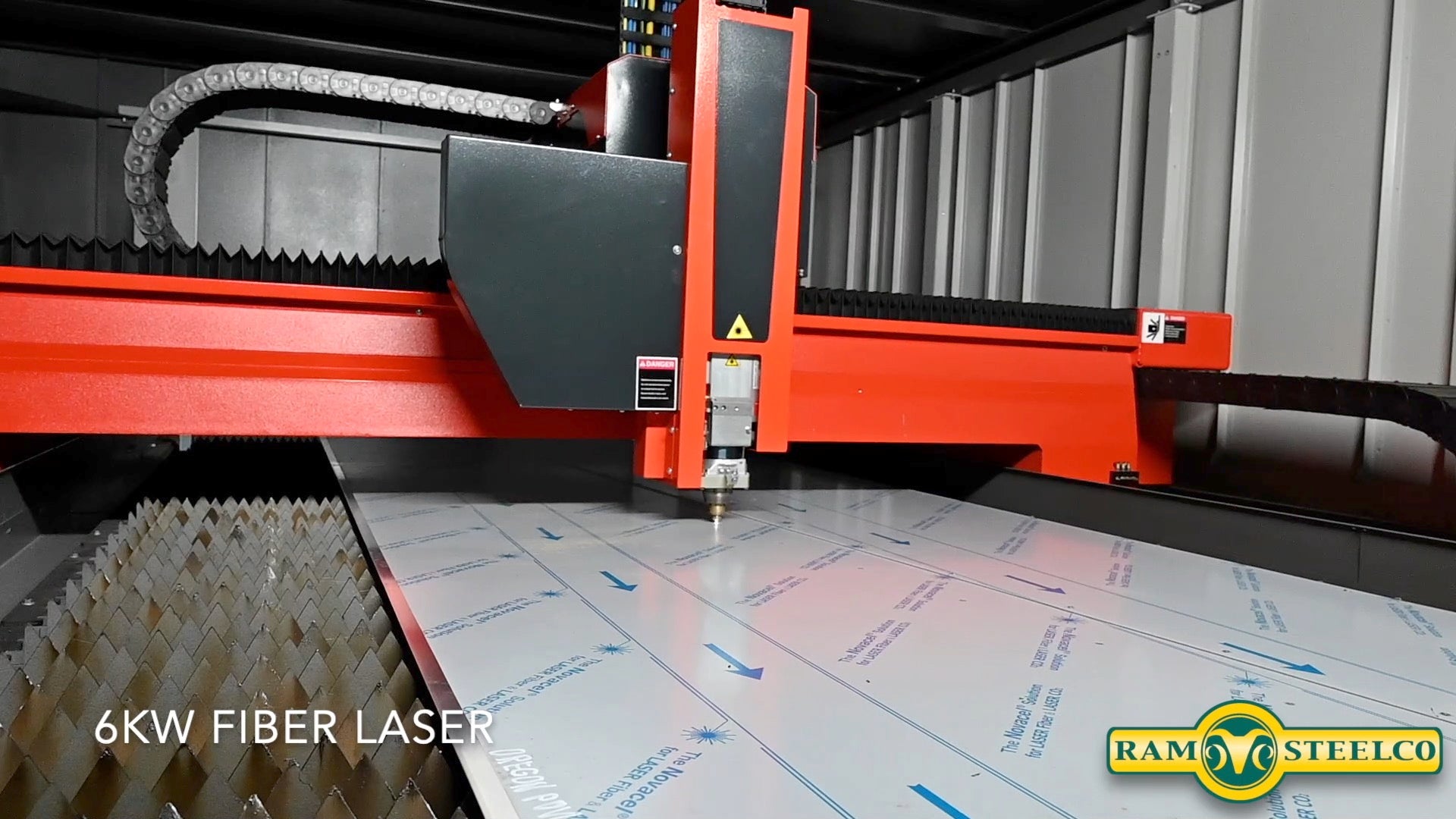

What is Laser Cutting?

Laser cutting utilizes a focused beam of light (laser) to melt, burn, or vaporize material, resulting in a precise cut. The laser is often guided by a computer numerical control (CNC) system, which allows for highly detailed and complex shapes.

What are the advantages to Laser cutting?

- Precision: Laser cutting offers exceptional precision and is capable of producing intricate designs and detailed cuts. It’s perfect for applications requiring tight tolerances.This method can cut through a variety of conductive metals, including steel, stainless steel, aluminum, brass, and copper. It's effective on thick materials, often up to several inches.

- Minimal Material Waste: The narrow kerf (width of cut) of a laser cutter means less material is wasted during the cutting process.

- Clean Cuts: The cuts are usually clean with smooth edges, reducing the need for additional finishing work.

- Automation: Laser cutting systems are highly automated, which reduces the need for manual intervention and increases production efficiency.

What are the key differences?

- Cutting Thickness: Hy-Def plasma is more effective for cutting thicker materials, often several inches thick, whereas laser cutting is typically used for thinner metals, usually up to about 1 inch.

- Material Flexibility: Plasma cutting can handle a wider range of materials, especially thicker metals, whereas laser cutting is more suited to precise, detailed work on thinner materials.

- Cost: Plasma cutting systems are generally more affordable to purchase and operate compared to laser systems. The consumables for plasma cutters are also less expensive.

- Speed vs. Precision: Plasma cutting is faster for thicker materials and less detailed work, while laser cutting is slower but provides higher precision and cleaner edges.

- Edge Quality: Laser cutting usually offers superior edge quality with minimal post-processing needed, whereas Hy-Def plasma, though improved, may still require some finishing

The choice between Hy-Def plasma and laser cutting depends on your specific needs:- If you need to cut thick materials quickly and cost-effectively, Hy-Def plasma is likely the better choice.- If you require highly precise cuts with clean edges, especially on thinner materials, laser cutting is the way to go.

Both technologies have their place in modern metalworking, and understanding their strengths and limitations will help you make an informed decision that suits your project's requirements.

CALL US TO DISCUSS YOUR NEXT PROJECT!

Stay connected with us on social media for industry insights, project showcases, and exclusive offers!

Learn About All Our Capabilities

- Laser Cutting

- Forming

- Hy-Def Plasma

- Rebar Processing

- Rolling

- Saw Cutting

- Shearing

- DXF & PDF Conversion